We take pride in delivering industrial and manufacturing projects that support regional economies and communities. From logistics facilities to laboratories, each project is built for longstanding quality and carefully tailored to facilitate the client’s commercial goals.

Selected projects

Selected projects

Selected projects

Selected projects

Selected projects

Selected projects

Industrial & Manufacturing

Recent projects

- Woolpoint Industrial

- Simplot - Project Potter

- Stockholm - Opal Group

- Aldi Merimbula

- SCT Logistics Rail Hub Centre

- Visy Board Pulper Building, Tumut

- Australian Airforce Flying Cadets (AAFC) Glider Training Facility

- ADI Munitions Plant and Explosive Test Facility, Benalla

- Multi Agency Depot, Albury

- Australian Newsprint Mill Recycled Fibre Plant, Albury

- Bombala Sawmill Expansion Project - Project NAMU, Bombala

- Charles Sturt University Integrated Field Laboratory (Rhisolysimeter), Wagga Wagga

- Charles Sturt University Private Road Works, Wagga Wagga

- Essential Energy, Cowra

- Elders, Albury

- Waste Transfer Station, Merimbula

- REX Australian Airline Pilot Academy (AAPA) Flight Simulator Building, AAPA

- Taronga Western Plains Zoo - Critical Breeding Elephant Facility, Dubbo

- TNT Depot, Albury

- Visy Board New Reel Store, Wodonga

- Visy Board Cardboard Plant, Wodonga

- Vitasoy, Baranduda

- Wilson Transformers Factory Expansion, Wodonga

- Wodonga Council Fatigue Management Centre and Trailer Interchange, Barnawartha

- Wodonga Institute of TAFE Motorsports Workshop, Barnawartha

- Wodonga TAFE - Driver Skills Training Centre + 1.6km Track Works, Barnawartha

- Wodonga TAFE Industrial Skills Training Block, Wodonga

- Zauril Aviation Hangar Complex, Albury

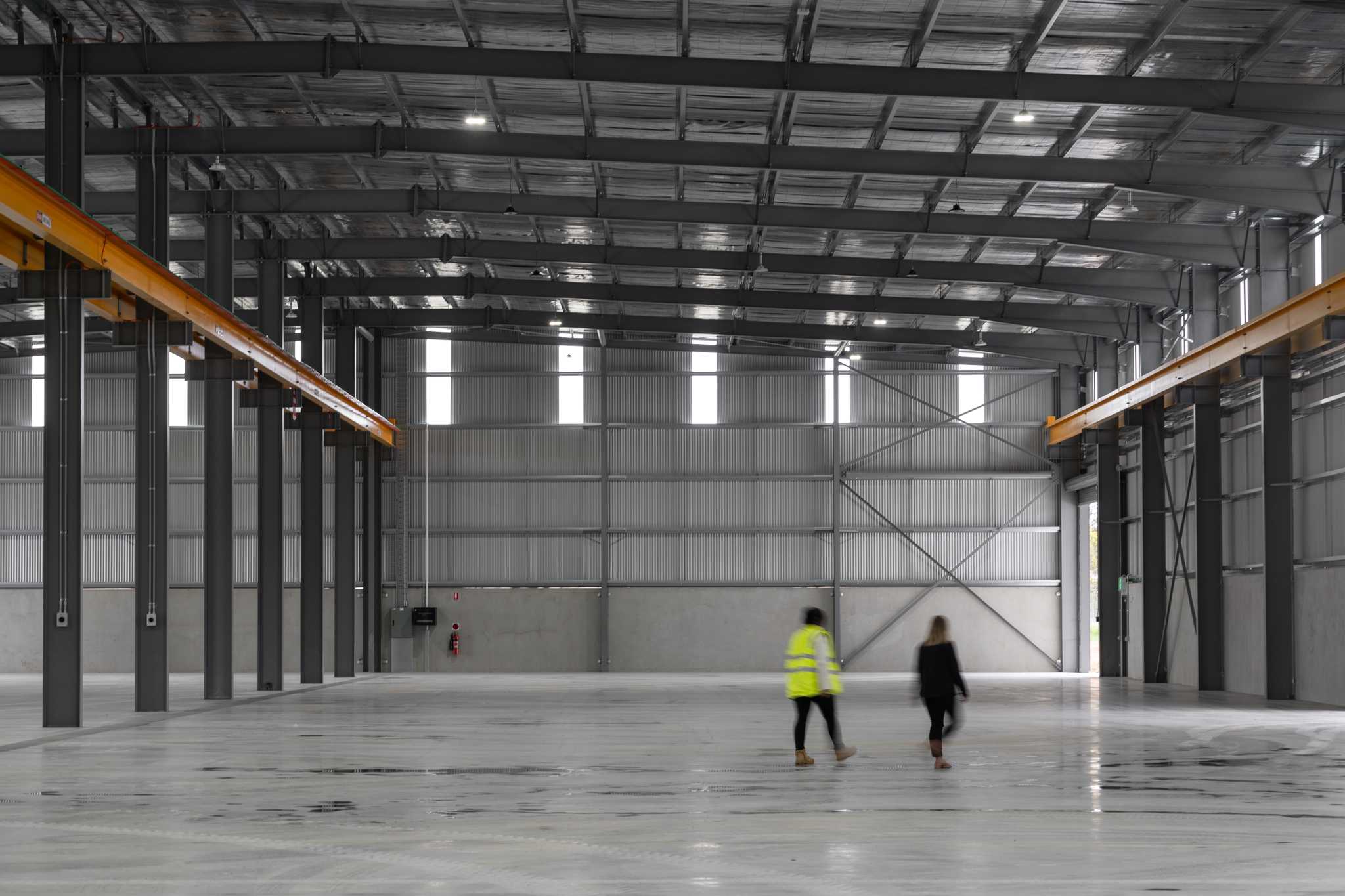

Woolpoint Industrial

Woolpoint Industrial Development includes a 4000m2 main warehouse, with 300m2 high-end office fit out and secondary 800m2 warehouse facilities. Extensive ground preparation works were completed to accommodate the B-Double Access and high-point load requirements for the manufacturing facility.

1/6

Woolpoint Industrial

Woolpoint Industrial Development includes a 4000m2 main warehouse, with 300m2 high-end office fit out and secondary 800m2 warehouse facilities. Extensive ground preparation works were completed to accommodate the B-Double Access and high-point load requirements for the manufacturing facility.

2/6

Woolpoint Industrial

Woolpoint Industrial Development includes a 4000m2 main warehouse, with 300m2 high-end office fit out and secondary 800m2 warehouse facilities. Extensive ground preparation works were completed to accommodate the B-Double Access and high-point load requirements for the manufacturing facility.

3/6

Woolpoint Industrial

Woolpoint Industrial Development includes a 4000m2 main warehouse, with 300m2 high-end office fit out and secondary 800m2 warehouse facilities. Extensive ground preparation works were completed to accommodate the B-Double Access and high-point load requirements for the manufacturing facility.

4/6

Woolpoint Industrial

Woolpoint Industrial Development includes a 4000m2 main warehouse, with 300m2 high-end office fit out and secondary 800m2 warehouse facilities. Extensive ground preparation works were completed to accommodate the B-Double Access and high-point load requirements for the manufacturing facility.

5/6

Woolpoint Industrial

Woolpoint Industrial Development includes a 4000m2 main warehouse, with 300m2 high-end office fit out and secondary 800m2 warehouse facilities. Extensive ground preparation works were completed to accommodate the B-Double Access and high-point load requirements for the manufacturing facility.

6/6

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

1/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

2/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

3/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

4/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

5/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

6/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

7/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

8/9

Stockholm – Opal Fibre Packaging

Zauner Construction completed the design and construction of Opal’s state-of-the-art, high speed manufacturing facility ‘Stockholm’ for the production of corrugated cardboard packaging. The factory is a total of 47,000m2, producing almost 400 tonnes of corrugated boxes a day.

The factory consists of the main production space, waste conveyor trench, service rooms including 2 x main switchboard rooms, dye room, wastewater treatment plant, control room and maintenance room.

The administration building includes office spaces, sales area, training rooms and kitchen facilities. Externally, the factory consists of the external roadway for truck deliveries and a separate dispatch office for the coordination of deliveries.

9/9

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

1/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

2/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

3/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

4/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

5/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

6/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

7/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

8/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

9/10

SCT Wodonga Rail Freight Centre, Barnawartha and SCT Logistics Wodonga

A purpose-built rail freight facility, the platform of SCT Logistics enables distribution of a wide range of rail freight – connecting Melbourne, Adelaide, Brisbane and Perth through this regional location.

Enabling B-Double road freight connection to railway freight through interconnected warehouse facilities, without compromising safety in design for operations, the efficiencies created in the nature of this project provide SCT Logistics with continued serviceability.

Management, administrative and inventory staff all operate from this location, including lunchrooms and amenities. Detailed fire services requirements along with complexity of transport safety were considered and successfully executed as part of this project delivery.

10/10

Zauner Construction has significant experience in construction of various industrial projects over 65 years company history.

Visy Board Pulper Building, Tumut

Working alongside an ongoing factory operational area, the staged upgrade of three key line process elements at Visyboard, Tumut included the installation of specialised plant, detailed coordination with structural foundations, integration of site services and delivery of operating equipment.

The Main Control Centre, the heart of factory operations, was upgraded to continue servicing the conveyor belt line, un-bailing machines and paper pulp operations. A 20 metre high paper mill was constructed of detailed concrete footings and slabs and 80 tonnes of structural steel to complete delivery of this operational upgrade.

1/5

Visy Board Pulper Building, Tumut

Working alongside an ongoing factory operational area, the staged upgrade of three key line process elements at Visyboard, Tumut included the installation of specialised plant, detailed coordination with structural foundations, integration of site services and delivery of operating equipment.

The Main Control Centre, the heart of factory operations, was upgraded to continue servicing the conveyor belt line, un-bailing machines and paper pulp operations. A 20 metre high paper mill was constructed of detailed concrete footings and slabs and 80 tonnes of structural steel to complete delivery of this operational upgrade.

2/5

Visy Board Pulper Building, Tumut

Working alongside an ongoing factory operational area, the staged upgrade of three key line process elements at Visyboard, Tumut included the installation of specialised plant, detailed coordination with structural foundations, integration of site services and delivery of operating equipment.

The Main Control Centre, the heart of factory operations, was upgraded to continue servicing the conveyor belt line, un-bailing machines and paper pulp operations. A 20 metre high paper mill was constructed of detailed concrete footings and slabs and 80 tonnes of structural steel to complete delivery of this operational upgrade.

3/5

Visy Board Pulper Building, Tumut

Working alongside an ongoing factory operational area, the staged upgrade of three key line process elements at Visyboard, Tumut included the installation of specialised plant, detailed coordination with structural foundations, integration of site services and delivery of operating equipment.

The Main Control Centre, the heart of factory operations, was upgraded to continue servicing the conveyor belt line, un-bailing machines and paper pulp operations. A 20 metre high paper mill was constructed of detailed concrete footings and slabs and 80 tonnes of structural steel to complete delivery of this operational upgrade.

4/5

Visy Board Pulper Building, Tumut

Working alongside an ongoing factory operational area, the staged upgrade of three key line process elements at Visyboard, Tumut included the installation of specialised plant, detailed coordination with structural foundations, integration of site services and delivery of operating equipment.

The Main Control Centre, the heart of factory operations, was upgraded to continue servicing the conveyor belt line, un-bailing machines and paper pulp operations. A 20 metre high paper mill was constructed of detailed concrete footings and slabs and 80 tonnes of structural steel to complete delivery of this operational upgrade.

5/5

Integrated Field Laboratory, Wagga Wagga

Charles Sturt University

Part of Charles Sturt University’s $45million National Life Sciences Hub project, the Integrated Field Laboratory supports soil and plant research and is the largest of it’s kind in the southern hemisphere.

The upgrade consisted of the additional of automated rainout shelters and two underground concrete bunkers which serve as laboratories to access the soil research facilities between 600mm and 2500mm under soil surface. The Rhizolysimeter technology interconnects to 96 research monoliths allowing study for soil core and root growth.

Supporting agricultural teaching and research, these facilities once again delivery world-class opportunity to regional areas – and we’re proud to continue to build and deliver in partnership with regional Australia.

1/7

Integrated Field Laboratory, Wagga Wagga

Charles Sturt University

Part of Charles Sturt University’s $45million National Life Sciences Hub project, the Integrated Field Laboratory supports soil and plant research and is the largest of it’s kind in the southern hemisphere.

The upgrade consisted of the additional of automated rainout shelters and two underground concrete bunkers which serve as laboratories to access the soil research facilities between 600mm and 2500mm under soil surface. The Rhizolysimeter technology interconnects to 96 research monoliths allowing study for soil core and root growth.

Supporting agricultural teaching and research, these facilities once again delivery world-class opportunity to regional areas – and we’re proud to continue to build and deliver in partnership with regional Australia.

2/7

Integrated Field Laboratory, Wagga Wagga

Charles Sturt University

Part of Charles Sturt University’s $45million National Life Sciences Hub project, the Integrated Field Laboratory supports soil and plant research and is the largest of it’s kind in the southern hemisphere.

The upgrade consisted of the additional of automated rainout shelters and two underground concrete bunkers which serve as laboratories to access the soil research facilities between 600mm and 2500mm under soil surface. The Rhizolysimeter technology interconnects to 96 research monoliths allowing study for soil core and root growth.

Supporting agricultural teaching and research, these facilities once again delivery world-class opportunity to regional areas – and we’re proud to continue to build and deliver in partnership with regional Australia.

3/7

Integrated Field Laboratory, Wagga Wagga

Charles Sturt University

Part of Charles Sturt University’s $45million National Life Sciences Hub project, the Integrated Field Laboratory supports soil and plant research and is the largest of it’s kind in the southern hemisphere.

The upgrade consisted of the additional of automated rainout shelters and two underground concrete bunkers which serve as laboratories to access the soil research facilities between 600mm and 2500mm under soil surface. The Rhizolysimeter technology interconnects to 96 research monoliths allowing study for soil core and root growth.

Supporting agricultural teaching and research, these facilities once again delivery world-class opportunity to regional areas – and we’re proud to continue to build and deliver in partnership with regional Australia.

4/7

Integrated Field Laboratory, Wagga Wagga

Charles Sturt University

Part of Charles Sturt University’s $45million National Life Sciences Hub project, the Integrated Field Laboratory supports soil and plant research and is the largest of it’s kind in the southern hemisphere.

The upgrade consisted of the additional of automated rainout shelters and two underground concrete bunkers which serve as laboratories to access the soil research facilities between 600mm and 2500mm under soil surface. The Rhizolysimeter technology interconnects to 96 research monoliths allowing study for soil core and root growth.

Supporting agricultural teaching and research, these facilities once again delivery world-class opportunity to regional areas – and we’re proud to continue to build and deliver in partnership with regional Australia.

5/7

Integrated Field Laboratory, Wagga Wagga

Charles Sturt University

Part of Charles Sturt University’s $45million National Life Sciences Hub project, the Integrated Field Laboratory supports soil and plant research and is the largest of it’s kind in the southern hemisphere.

The upgrade consisted of the additional of automated rainout shelters and two underground concrete bunkers which serve as laboratories to access the soil research facilities between 600mm and 2500mm under soil surface. The Rhizolysimeter technology interconnects to 96 research monoliths allowing study for soil core and root growth.

Supporting agricultural teaching and research, these facilities once again delivery world-class opportunity to regional areas – and we’re proud to continue to build and deliver in partnership with regional Australia.

6/7

Integrated Field Laboratory, Wagga Wagga

Charles Sturt University

Part of Charles Sturt University’s $45million National Life Sciences Hub project, the Integrated Field Laboratory supports soil and plant research and is the largest of it’s kind in the southern hemisphere.

The upgrade consisted of the additional of automated rainout shelters and two underground concrete bunkers which serve as laboratories to access the soil research facilities between 600mm and 2500mm under soil surface. The Rhizolysimeter technology interconnects to 96 research monoliths allowing study for soil core and root growth.

Supporting agricultural teaching and research, these facilities once again delivery world-class opportunity to regional areas – and we’re proud to continue to build and deliver in partnership with regional Australia.

7/7

Other sectors

Back toConstruction